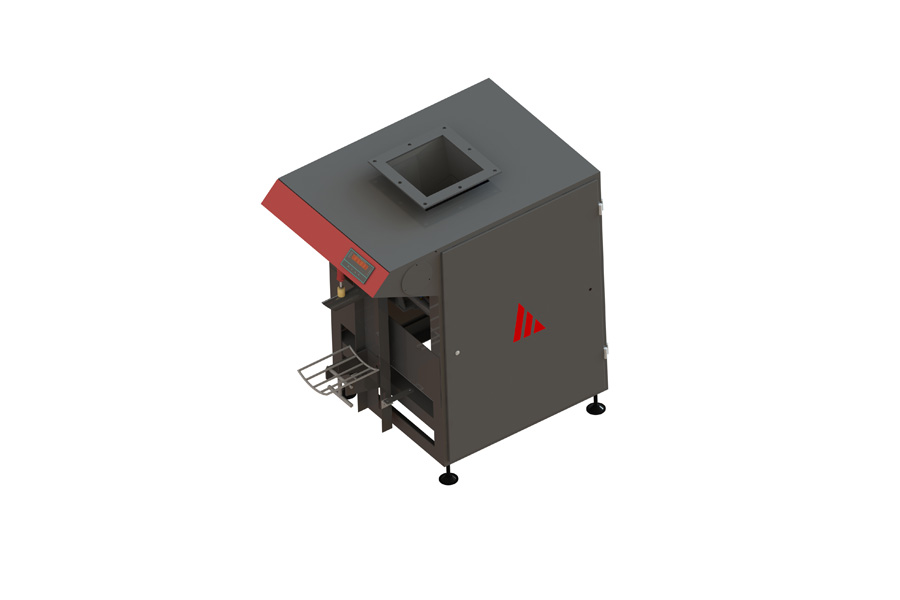

Simple dry mortar mix plant- 1-8 TPH

Less investment, The max height is around 4 meters in a small work area. The simple dry mortar production line consist of the feeder conveyor, dry mortar mixer, screw conveyor, finished storage silo, The optional devices are simple dust collector and the automatic packing machine.

The dry mortar mixer have the recycling time of 15-20 minutes per batch, the continious running make sure the urgent request is possible.

* The structure will be different as customers’ requests.

What is dry mortar?

If you ask the construciton materials dealers, what is dry mortar? They will tell you directly, those bags over there, 25 KGS one bag or 15 KGS one bag, the grey or white powder inside, yes, those were dry mortar! Generally saying, the dry mortar mainly consist of cement and special additives, which always packaged by 25 KGS per bag, mixing water into them to bond the blocks, bricks and cermic tiles in the work site .

Mentioning the ingredients of dry mortars, the points will get our attentions as below:

*Any technical request cuold be realized by different ingredients in dry mortars

*The better of the remixability of the ingredients, the better performance of the dry mortar.

*The ingredients are different because of the environment of the construction sites like the rainy seasons and the hot seasons

*The reasonable price, lower costcan also get the good performance

*Try to make the ingredients simple, the experience and the trial run will help you.

*The trila run is different from the bulk using in work site. Make adjustment to get the proper ingredients suit to the construction sites.

Applications of Dry Mortar Mix Plant?

1. Wall putty mortar

• Less paint consumption, make project budget lower.

• Strong adhesion and flexibility

• Moisture and aging resistance.

• Natural materials make sure the environmental safe.

• Good air permeability and less crack.

• Good surface decoration

• Fireproof and insulation

2. Masonry mortar

• Bonding bricks, blocks and other stones..

• Masonry mortar can ensure the stability of the mortar because of the strong plasticity and low shrinkage.

3. Tile adhesives

• Tile adhesives can effectively reduce delamination, peeling, avoid hollowing, cracking, etc.

• Absolutely protecting the environment without toxic additives.

4. Tile grout

• Grouting walls or floors between tiles.

• Low shrinkage rate, reduce crack formation

• Low water absorption and strong resistance to penetration

5. Thermal insulation mortar

• It can be used after adding water, forming a thermal insulation layer.

• Thermal insulation mortar has stable performance, low shrinkage, and can effectively prevent mortar cracking.

• The environmentally-friendly thermal insulation effection of the thermal insulation mortar is very good even the moisture of circumstance is high.

6. Plastering mortar

• Applied on the surface of buildings or building components.Strong ability to withstand external action.

• High resistance to water flushing. It is a very good choice for using plastering in the bathroom or other damp rooms.

• Reduce the number of plastering layers and improve work efficiency.

• The fluidityof plastering mortar is excellent and easy to smooth.

7. Gypsum joint mortar

• Joints of gypsum board and cement fiber board.The green building materials without cracking.

• Easy to polish, easy to stir, fast drying with good bonding effect.

8. Decorative mortar

•The decorative mortar can directly decorate buildings without smooth base or other decorative treatment, replacing paint or tiles with lower cost.

• Strong adhesion, low water absorption and good air permeability with convenient construction and easy operation.

9. Self-leveling mortar

• Leveling the base of various floor materials without segregation, the mortar has good fluidity and can be leveled automatically within a limit thickness.

• According to your requirements, the formulation can be adjusted to change the bearing capacity of the mortar.

•Dry in a short time. Strong adhesion, Low shrinkage, environmentally-friendly materials

Specifications

dry mortar mixer

dry mortar storage silo

dry mortar packing machine

| Items | Equipment | Unit | Quantity |

|---|---|---|---|

| 1 | Feeder | set | 1 |

| 2 | Screw cnveyors | set | 2 |

| 3 | Dry mortar mixer | set | 1 |

| 4 | Automatic packing machine | set | 1 |

| 5 | Finished product silo | set | 1 |

To see our manufacturing ability

Options

| Options |

| Air compressors |

| Automatic packing machine |

| Customized finished product silo |

| Structure customization |

| Colors customization |