Self leveling mortar plant – floor mortar production line Full FAQs

What is self leveling mortar?

Self-leveling mortar is a ready use mortar, which should be mixed with water before using it directly. Moreover, it is used to create a flat and smooth surface with a compressive strength similar to or higher than the conventional cement mortar, and it is mainly used as an underlayment or as a topping. For underlayment, it is installed over a subfloor to smooth it or to correct and fix any irregularities on the surface prior to the installations of all floor coverings. Self leveling mortars mainly includes cement, sands, etc. Besides of the dry bag Self leveling mortar, the trailer mortar truck can loaded the bulk Self leveling mortar in a huge tank of 30CBM, 40CBM, 50CBM, 60CBM, etc.

What is self leveling mortar plant?

The name “self leveling mortar plant” shows that it is a kind of equipment that could produce the Self leveling mortar. Whatever the mini self leveling mortar production line or the huge Self leveling mortar factory. The whole line totally includes raw materials storage system, weighing system, mixing system, packing system, dust collecting system, end product store system and control system

By output and operation, three families of self leveling mortar plants are:

Mini self leveling mortar production line– With the capacity 1-8 TPH, the mini Self leveling mortar production line is consist of material feeder, one level screw conveyor, belt screw mixer, second screw conveyor, finished products silo, automatic packing machine, control cabinet and air compressor.

Semi automatic Self leveling mortar mix plant– With the capacity of 10-40 TPH, the semi-auto Self leveling mortar manufacturing plant is composed of bucket elevator, weighing system, ready-mix silo, twin-shaft mixer, pre-packing silo, automatic packing machine.

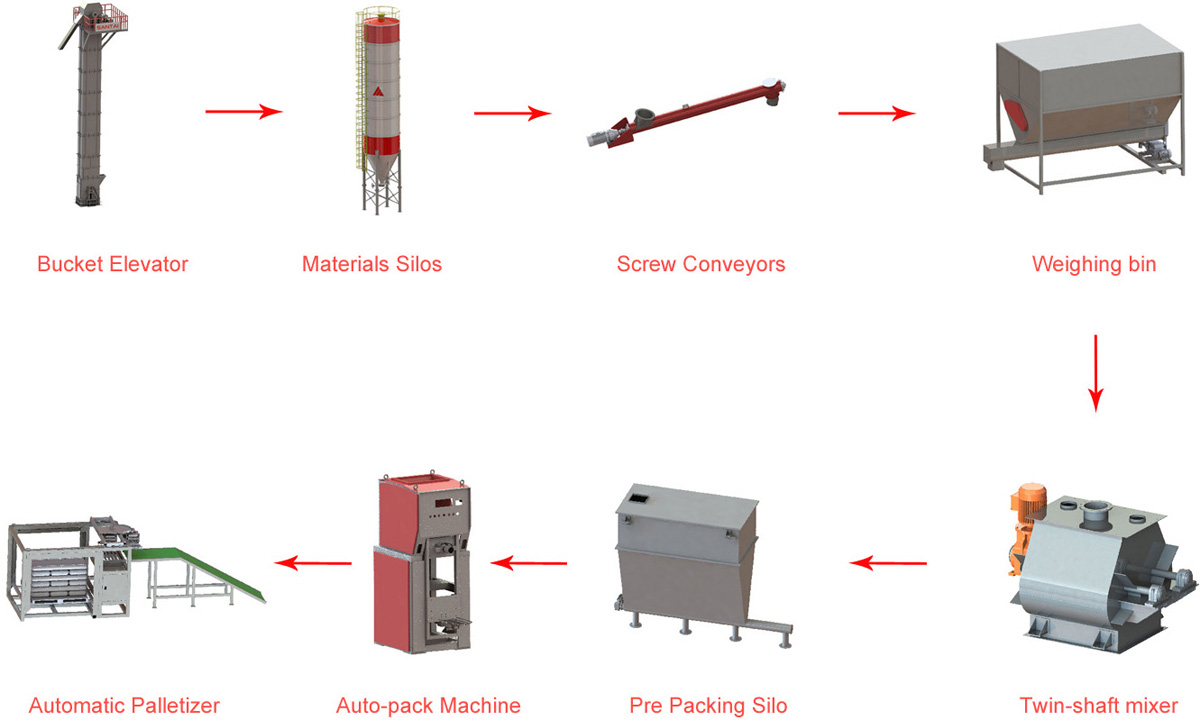

Full automatic Self leveling mortar plant– with the output from 10-100 TPH, the full-auto Self leveling mortar plant have the perfect structure is that Raw materials silos, screw conveyors, bucket elevator, weighing system, ready-mix silo, twin-shaft mixer, pre-packing silo, automatic packing machine, automatic palletizers.

The advantages of a full automatic Self leveling mortar plant are as below:

*The formulations could be adjusted slightly and precisely by your real situations and detailed requests.

*The PLC control system will give the whole line full automatic operations. The touch screen will give you a “what you see is what you get” experience.

*The automatic palletizers will give the total plant high efficiency and make the full output of the Self leveling mortar plant.

*The raw materials storage silos save the feeding time and also make the quantities of labor as less as possible.

The sections of self leveling mortar plants

The parts of the automatic self leveling mortar plant as below:

* Storage system-Raw materials silos, normally the standard 100 tons cement silos are the main storage devices. Sands, cement, fly ash and other request raw materials were lifted to the silos by bucket elevators.

* Weighing system– The materials step by step go into the weighing silo and scale. Sometimes the other additives have a separate weighing bin.

* Mixing system– Non-gravity twin-shaft mixer with the excellent sealing, Mn13 Alloy blades, planetary cycloidal reducer and copper core motors make sure the durability and stability of the mixer.

* Automatic packing system-The valve packing machine fill the bags with pneumatic system with the range from 10-50 Kgs. The machine have the capacity of 6-10 seconds per bag packing.

* Bulk loading system– The powder loading system will be used when you need to fill the thermoplastic road mark paint to the tank. The flexible pipe could down to the tank from 1500MM-2500MM.

What self leveling mortar plant suit your request?

1-8 TPH mini self leveling mortar production line match the compact work site, limited budget, own use and some for selling.

10-40 TPH self leveling mortar plant suit enough workspace, bigger investment, the own big project using or the construction materials manufacturers and suppliers in your local.

The motors and reducers in self leveling mortar mix plants

The important section of a motor is the core. There are some aluminum core meanwhile some copper cores. That is the 100% copper core in our motors that are installed on our self leveling mortar plants.

The reducers are used in the self leveling mortar mix plants are generally two types the gear reducer and the cycloidal planetary reducer. The cycloidal reducer have a smaller size, 2-3 times durability than the gear reducer. Ther are cycloidal reducers in our self leveling mortar plants.

Should I choose the automatic palletizer?

If you use the mini self leveling mortar manufacturing line, basically no need to use the automatic palletizer.

If the output of your self leveling mortar factory is more than 10TPH meanwhile there have no extra labors to use, you can choose the automatic palletizer.

The transport of self leveling mortar plants

Mini Self leveling mortar plant normally need one 20 feet container to load.

A semi-auto Self leveling mortar mix plants request the 1.5-4 sets 40 feet containers to transport.

A full-auto Self leveling mortar plant demand 3-10 pieces 40 feet containers to ship.

The price of self leveling mortar plants

Mini Self leveling mortar plant price range is 4,000-8,000 USD.

A semi automatic Self leveling mortar mix plant price range is 12,000-40,000 USD.

A full automatic Self leveling mortar plant cost range is 30,000-500,000 USD.