Automatic dry mortar mix plant | dry mortar production line manufacturer

The components of the completed automatic dry mortar mix plant are sand drying line, dry mortar feeding bin, raw materials silos, twin-shaft paddle mixer, bucket elevators,pre-mix hopper, additive hopper, finished product silo, bag dust collector, automatic batching machine, steel frame, etc. The raw materials silos normally are used to store the raw materials like cement, fly ash, sand, and others.

The 20-40 TPH dry mortar mix plant solutions could be the double 10-20 TPH dry mortar production line configuration while could be the single bigger mixer configuration.

As the dry mortar mix plant manufacturer, SANTAI give the professional dry mix solutions that could produce the products like wall putty mortar, masonry mortar, plastering mortar, thermal insulation mortar, self-leveling mortar, etc.

Work area:60-100 M2

Mixer volume: 2-3-4 M3

Manpower: 3-4 person

* The structure will be different as customers’ requests.

What is dry mortar?

If you ask the construciton materials dealers, what is dry mortar? They will tell you directly, those bags over there, 25 KGS one bag or 15 KGS one bag, the grey or white powder inside, yes, those were dry mortar! Generally saying, the dry mortar mainly consist of cement and special additives, which always packaged by 25 KGS per bag, mixing water into them to bond the blocks, bricks and cermic tiles in the work site .

Mentioning the ingredients of dry mortars, the points will get our attentions as below:

*Any technical request cuold be realized by different ingredients in dry mortars

*The better of the remixability of the ingredients, the better performance of the dry mortar.

*The ingredients are different because of the environment of the construction sites like the rainy seasons and the hot seasons

*The reasonable price, lower costcan also get the good performance

*Try to make the ingredients simple, the experience and the trial run will help you.

*The trila run is different from the bulk using in work site. Make adjustment to get the proper ingredients suit to the construction sites.

Specifications

Bucket Elevators

Raw materials storage silo

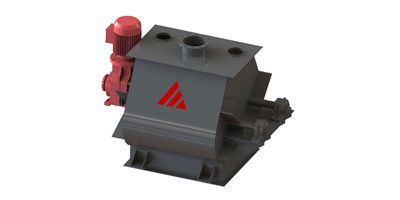

Twin-shaft dry mortar mixers

Bag dust collectors

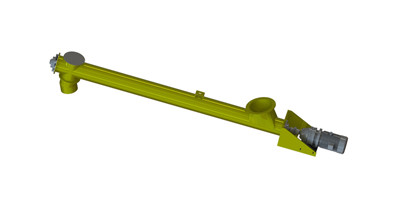

Screw conveyors

Automatic packing machines

| Items | Equipment | Unit | Quantity |

|---|---|---|---|

| 1 | Feeder | set | 1 |

| 2 | Screw conveyors | set | 2 |

| 3 | Raw materials storage silo | set | As request |

| 4 | Weighing system | set | 1 |

| 5 | Twin-shaft dry mortar mixer | set | 1 |

| 6 | Automatic packing machine | set | 1 |

| 7 | Finished product silo | set | 1 |

To see our manufacturing ability

Options

| Options |

| Air compressors |

| Automatic packing machine |

| Customized finished product silo |

| Structure customization |

| Colors customization |